[Aluminum Road Network] Thermal transfer technology has been applied to fabric transfer printing very early. With the rapid development of science and technology, thermal transfer technology has become more and more widely used. Thermal transfer and sublimation pressure transfer type and sublimation transfer type, this article discusses the popular sublimation transfer in the powder industry. The transfer of fine patterns onto the powder coating to change the appearance of wood grain or other patterns on the metal surface has become a popular trend. The application of this green technology has changed people's dependence on solid wood and reduced the excessive logging of forests. . The technology was jointly developed by Italian powdered polyester resin manufacturers including Tema, powder coating manufacturers, sprayers and users in accordance with the market's pursuit of fashion trends in the 1990s, and successfully applied to profiles and various On the substrate. Figure 1 shows the development and development of thermal transfer resins.

1 thermal transfer technology basis

1.1 wood grain heat transfer process

The dye-sublimation dye ink is printed onto a transfer paper or a transfer film, and the transfer film/paper pattern is then transferred onto the powder coating by a combination of vacuum, heat and pressure.

1.2 Sublimation / Sublimation

Sublimation is a process in which a substance changes from a solid directly into a gas, and desublimation is the change in the matter from a gas directly to a solid. The high temperature causes the solid dye to sublimate and detach from the transfer paper or film to penetrate into the powder coating structure. After sublimation, the dye is cooled and desublimated into a solid state, thereby becoming part of the powder coating.

1.3 dye ink

The solid ink sublimates under heating to a gas and can be converted into a solid again under cooling.

1.4 transfer paper or transfer film

Pattern design, printing and transfer reproduction of the carrier.

1.5 substrate

Resistant to 200°C metal or other substrates, including ceramic, glass and high and low light powder coating decorative substrates.

2 thermal transfer applications

Where there is a change in appearance, there is a transfer. According to the market segmentation, powder thermal transfer printing is widely used in construction, transportation, general industry and home appliance fields, such as doors and windows, garages, decorative ceilings, store fixtures, shelves, display cabinets, desks, awnings, benches, tables Chairs, decorative platforms, handrails, appliances, kitchen utensils, refrigerators, barbecue equipment, bells, sun rooms and luxury yacht interiors. A detailed overview is shown in Figure 2.

3 sublimation thermal transfer mechanism of powder coating and influencing factors

3.1 transfer mechanism and process flow

Usually the material is divided into four states, namely solid, liquid, gas, and plasma states. Figure 3 describes the transition between phases. Sublimation thermal transfer is the use of dye inks for sublimation and desublimation to achieve dye molecules from transfer paper or The osmotic migration of the transfer film to the powder coating of the substrate allows the transfer of the pattern, resulting in the formation of a grain or other desired effect. Figure 4 shows the transfer process.

3.2 Factors Affecting the Transfer

The effect of the transfer depends on many factors. It is important to consider the pretreatment of the substrate, the degree of curing of the powder coating, the degree of coating of the transfer film on the substrate, the transfer temperature, the design of the pattern, and the quality of the ink. The following discussion focuses on the effects of resins, inks and formulations.

3.3 The effect of resin on thermal transfer

The resin is largely determined by the important chemical factors behind the application. The specially designed high-performance functional resin has the following features. Good resin is made of thermal transfer powder coating, which should have easy tearing, accurate reproduction, high definition, highly stable gloss control, excellent chemical and weather resistance, and full stability to make the process more convenient. Simple, non-volatile technology, excellent flow smoothness, high cross-link density, and compliance with stringent Qualicoat and GSB standard requirements. Specific to the resin parameters, should have a higher acid or hydroxyl value.

3.4 Effect of dye ink on transfer effect

The depth of the dye ink into the coating determines the quality and stability of the pattern. At the same time, the dye ink greatly influences the color plumpness, color fastness, and color retention time of the wood grain or other transfer effects. Through the analysis of the cross-section of the transfer template, it was found that the depth of ink entering the powder coating was about 50%; the fullness of the transfer pattern was better. Of course, many other factors also affect the quality of the transfer pattern.

3.5 thermal transfer powder coating formulations

In the early development stage of thermal transfer, European powder coating engineers used hydroxy-terminated polyester resin and isocyanate curing agent as thermal transfer, and high-low hydroxy one-step extrusion became a classic low-light solution with low gloss and high plumpness. And with a smooth feel. For example, after listening to Albester Silky Matt 3115 (290 OH) and Albester Silky Matt 3225/3600/3120 (about 50 OH), the heat transfer in Guangdong, China, after transfer technology was studied and used by Chinese powder engineers. India's printing technology has mushroomed and developed into a powder-transfer technology in China. Among them, high acid value outdoor polyesters and hydroxyl-terminated polyesters and polyurethane curing agents and TGIC curing are more popular, such as listening to Albester Silky Matt. 5900 (90:10TGIC)/Albester 3310 (110 hydroxyl value), this system combines the advantages of TGIC system and polyurethane system, high cross-link density, easy to tear paper, high fullness, and vivid wood grain after transfer. In addition, very innovative Chinese powder engineers have developed skin grain, GMA systems and super weathering woodgrains.

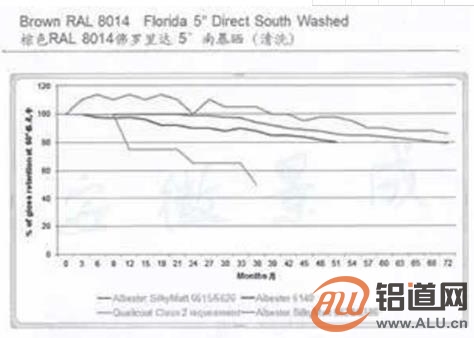

3.6 super heat-resistant thermal transfer

With the development of woodgrain transfer, more and more wood grain profiles are used outdoors, and strong UV light constantly tests the weather resistance of wood grain. At the same time, European Qualideco also introduced wood grain powder coating and wood grain printing. Certification requires powder coating to achieve grade 2 super weather resistance. Several transfer film (paper) manufacturers in Italy have also stepped up the development of super weathering transfer films. Tema has introduced a series of super weather resistant polyester solutions, such as Albester 6140 (93:7TGIC super weathering), Albester Silky Matt 6520/6580 (TGIC/HAA dual system low light super weathering) and AlbesterSilkyMatt6615/6620 (polyurethane low hydroxyl low light (Super weather resistance) can meet Qualideco/Qualicoat powder coating level 2 requirements. Figure 6 shows the results of some products in Florida. At present, in the transfer film field, only some of the color transfer films can meet the requirements of super weathering grade 2, yet the upstream sublimation transfer ink manufacturers need to overcome the level 2 weathering requirements of all popular color systems.

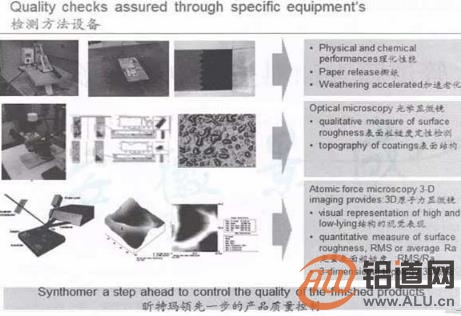

3.7 sublimation thermal transfer quality assurance

The introduction of QTMAR products or product lines must undergo rigorous testing and inspection studies, including physicochemical properties / tearing paper / accelerated aging and other properties. Optical microscopy and 3D atomic force microscopy are used for qualitative and quantitative tests to verify that the product meets design and application requirements. It is of great significance for studying the one-shot low-light effect of polyurethane.

4 Conclusion

Tema strategy supports woodgrain transfer, invests heavily in research and development of woodgrain transfer resin solutions, and launches a series of woodgrain transfer printing programs covering polyurethane one-step low-light/half-light systems, TGIC&HAA curing systems, and pushing woodgravure transfer. The intrinsic quality upgrade of printed products satisfies outdoor weathering applications. Super weathering wood grain came into being.